The Role of Packaging Machine Repair in Preventing Costly Production Halts

Just How to Optimize Performance With Expert Packaging Device Repair Work Solutions

In today's affordable landscape, the efficiency of packaging operations directly effects general efficiency and productivity. Recognizing the critical role of packaging machines, companies should acknowledge the indications that indicate a need for repair work and the advantages of engaging specialist solutions. By focusing on expert repair work services, organizations can not only minimize downtime yet additionally improve the durability of their equipment. Nevertheless, selecting the right fixing solution and carrying out efficient preventative maintenance strategies continues to be essential. Exploring these elements can expose techniques that significantly boost operational efficiency, motivating a better examination of best methods in this essential location.

Comprehending Product Packaging Device Relevance

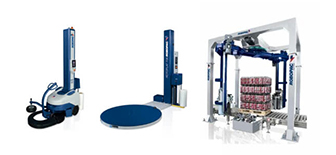

Product packaging equipments play an integral role in improving operational effectiveness, item conservation, and customer allure. High-speed product packaging equipments can streamline production processes, reducing labor costs and reducing human error, while preserving high throughput rates.

Furthermore, advanced packaging devices are developed to accommodate numerous product packaging kinds, such as containers, bags, and boxes. This adaptability enables producers to adapt to transforming market needs and consumer choices without substantial downtime. Furthermore, effective product packaging makes sure product integrity throughout transportation and storage space, minimizing waste and putridity and ultimately adding to sustainability efforts.

In addition, product packaging makers integrate flawlessly with other manufacturing systems, assisting in a smooth workflow from manufacturing to distribution. This interconnectedness not just improves performance however also gives important information analytics for constant renovation. In summary, the relevance of packaging equipments in modern production can not be overstated; they are necessary for maintaining affordable benefit and accomplishing functional quality in today's hectic organization environment.

Indications Your Equipment Requirements Repair

Recognizing the signs that your packaging maker calls for repair work is critical for maintaining production performance and minimizing downtime. Regular tracking of equipment performance can help discover concerns prior to they escalate into considerable troubles.

One of the initial indicators is an unusual boost in sound degrees throughout operation. It might suggest mechanical wear or imbalance if the equipment starts to produce grinding or clattering sounds. Additionally, inconsistent product output, such as irregular packaging or mislabeling, can recommend that the maker's calibration is off, calling for prompt focus.

An additional critical sign is regular error messages or unexpected shutdowns. These disruptions can significantly affect outcome and signal underlying electrical or software issues. Furthermore, if you discover a decline in speed or performance, with the equipment taking much longer to finish tasks, it may be a precursor to extra extreme mechanical failings.

Lastly, physical signs such as fraying belts, dripping liquids, or excessive resonance needs to not be neglected, as they typically indicate components that get on the verge of failure - packaging machine repair. Immediately addressing these signs can avoid costly fixings and make sure optimal functional performance

Advantages of Expert Repair Work Providers

Furthermore, professional repair services often have accessibility to innovative analysis tools and innovations that help with a comprehensive assessment of equipment problem. This not just aids in immediate fixings yet likewise enables predictive upkeep, stopping future malfunctions and extending the lifespan of equipment.

Furthermore, utilizing specialist services can lead to boosted safety and security requirements, as experienced specialists are well-versed in sector guidelines and best techniques. This minimizes the risk of crashes brought on by improper handling or upkeep. Eventually, the investment in expert repair solutions translates to set you back savings by maximizing device efficiency, improving item high quality, and making certain compliance with safety and security requirements, every one of which add to a much more effective manufacturing atmosphere.

Picking the Right Repair Work Solution

A repair solution that offers 24/7 assistance can avoid small problems from rising into pricey production stops. Look for companies that give a comprehensive solution contract, outlining their service warranties, pricing frameworks, and parts accessibility.

Guarantee that the service technicians are accredited and trained in the most current innovations and finest methods, as this know-how is necessary for reliable repair services and maintenance. By carefully selecting a repair service, you can improve the durability and performance of your packaging equipments.

Preventative Upkeep Methods

Carrying out preventative upkeep techniques is important for guaranteeing the optimal efficiency and durability of packaging go to these guys machines. Consistently set up maintenance not only lowers the probability of unforeseen breakdowns yet likewise enhances total operational performance.

A proactive upkeep routine ought to consist of routine inspections, lubrication of relocating parts, and looking for deterioration on crucial parts. These assessments can identify possible issues prior to they escalate right into costly repair services or downtime. Furthermore, maintaining precise records of great post to read maintenance tasks can assist track equipment performance fads and guide future maintenance choices.

Training employees on proper operating treatments is another crucial aspect. Workers need to be educated on acknowledging very early signs of maker breakdown, which can facilitate timely treatment. Additionally, employing resonance analysis and thermal imaging technology can even more enhance the maintenance method by determining issues that may not show up to the nude eye.

Final Thought

Finally, taking full advantage of efficiency with expert product packaging equipment repair service services requires a positive technique that includes regular upkeep, timely repair work, and the knowledge of experienced technicians. Carrying out innovative analysis tools and cultivating connections with reputable fixing solutions contribute to boosted operational efficiency and decreased downtime. By prioritizing these techniques, businesses can make sure the longevity and performance of their packaging equipment, ultimately bring about enhanced performance and adaptability in feedback to developing manufacturing demands.

Comprehending the crucial duty of packaging makers, businesses should identify the signs that suggest a demand for repair work and the benefits of involving expert services.Resolving the signs of wear and malfunction in product packaging machines quickly is only component of the formula; leveraging professional repair work solutions can dramatically enhance operational effectiveness.Choosing the appropriate packaging equipment repair service is important for keeping functional efficiency and decreasing downtime. By thoroughly picking a repair solution, you can boost the longevity and performance of your packaging devices.

In final thought, taking full advantage of performance with expert packaging device repair work services requires a positive technique that consists of routine maintenance, timely repair services, and the expertise of experienced specialists.